Automatic storage and feeding

Automatic storage (“input”) in containers and feeding (“output”) of tubes and rod-shaped parts ‐ fast, cost-effective and reject free.

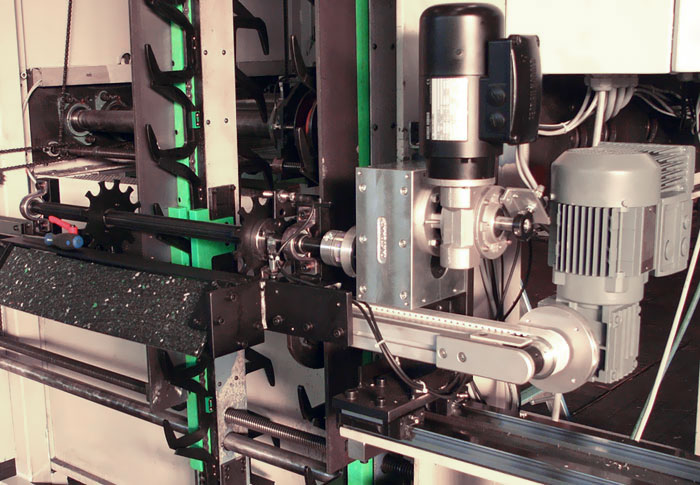

Functionality of the storage system for pipes

Pipe sections that are output from an automatic pipe cutting machine after the cutting process are automatically fed to the magazine, i.e. the input unit, by a conveyor system and accepted.

Belts take up the pipe sections. The belts lower automatically as filling increases. The pipes lie one above the other in the belts and thus automatically take up the smallest possible space. An intermediate buffering system ensures a continuous transfer of the pipe sections.

The pipe sections are automatically picked up from magazine containers. After filling, the magazine containers can be moved to another location for unloading to an output unit.

An automatic lifting of the belts transports the pipe sections out of the magazine. The integrated separating device in combination with a handling device or a robot ensures the automatic transfer of the individual pipe sections to the further processing machine.

The input and output units are installed stationary at the place of use. The containers are transported from the input unit to the output unit. This allows intermediate storage of workpieces of any size.

Download description of functionality

Benefits to increase productivity

- Automatic regulation of the discharge speed by the controller according to the cycle time of the connected processing unit.

- Automatic “Full-Empty” message

Loading

- organized storage

- minimal space requirement

- gentle parts treatment

- any intermediate storage

Unloading

- quick and safe removal

- minimal time requirement

- easy-to-use

- low personnel costs

- fully automatic transfer

Further benefits of the system

- economical lot sizes even for small quantities, e.g. 250 pieces

- Savings through reduced machine use

- Improved workflow

- less waste